3 common biomass boiler auger problems

We explore some common issues that can occur with augers and suggest how to resolve them or stop them from occurring.

1. Overcurrent errors

Most biomass boilers will monitor the amperage drawn from your auger drive motors – this is to protect the motor from burnout.

Most quality biomass boiler manufacturers use 2 types of auger motor protection to ensure the motor does not burn out. Firstly, digital amperage monitoring where the PLC monitors the amperage being pulled from the motor. When an electric motor works harder, it draws more amperage from the source, giving an early indication to the PLC that there is a problem. In addition to this, many boilers will use a second line of defence in the form of a physical thermal trip which will be set to the motor limit. If the digital monitoring fails, or there is a sudden spike in amperage, this second line of defence will trip and kill power to the motor.

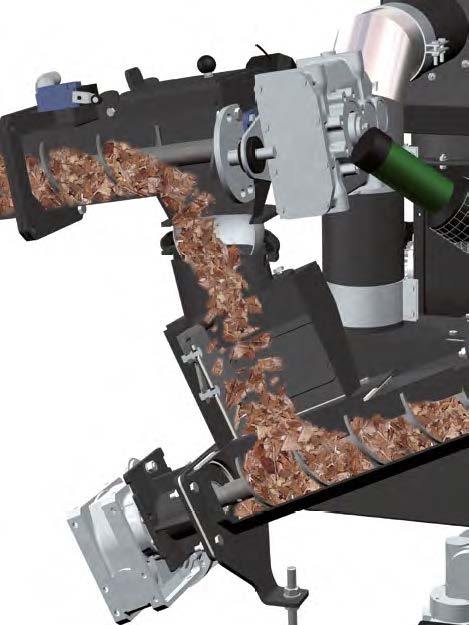

Common causes for motor protection errors/alarms are feed auger blockages, generally caused by oversized chip jamming within the auger channel or between the flight of the auger and the sheer edge.

Blockages in rotary valves are often caused by twigs and oversized chips blocking the exit of the drop shaft or wet chip becoming compacted in the drop shaft. Most 3 phase motors will have the facility to run in reverse manually and this will often release the blockage. However, depending on the location of a jam or blockage, it will require manual intervention which depending on the location of the jam can be straightforward or many hours of work.

Note: Auger drives and solid fuel feeding systems can be extremely dangerous. Powerful motors emit huge forces and can cause injury or damage – you should never insert hands or tools into the auger channel unless correct isolation and locking-off procedures have been used.

2. Gear box failure

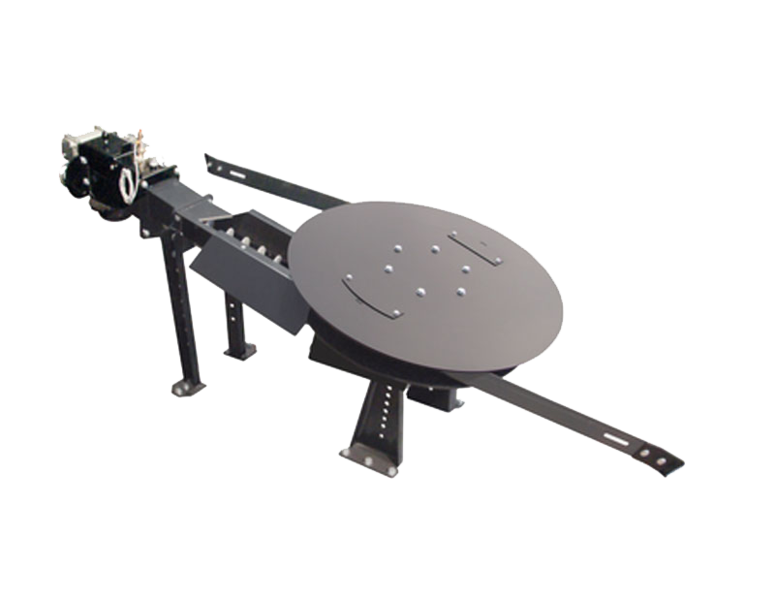

Many auger agitators setups use a single motor drive and the auger itself connects to a low-end gearbox which drives and rotates the agitator arms – if not installed correctly, or properly maintained, constant strain on the gearing can lead to failure.

Spring blade and torsion arm agitators are designed to move through the chip with the least resistance as possible while agitating and scraping chip into the auger channel – if these arms are installed incorrectly or not maintained they can create huge resistance against the wood chip and so put excessive force on the gearing. In some cases, we have found gearbox gearing to have completely shattered due to excessive torque or resistance. Due to the location of gearboxes being at the bottom of the fuel store and a floor built on top of them, it is normally a fairly large job to remove and replace.

These types of failures could be avoided by periodically checking agitator blades or agitators for correct function and tightness and ensure the top hat/turntable is not binding or catching on the fuel store or auger channel.

3. Bridging of fuel

When using very coarse or elongated fuel (shredded fuel), it can builds up as a nest, causing some spring blade agitators to struggle agitating the fuel into the fuel channel – if this problem occurs, usually a torsion arm agitator is a better solution and tends to break up the bridging of the coarse fuel.

Request a callback

If you want to get a quote or simply ask a question, fill in your details on our Contact Page.