3 reasons a biomass boiler buffer tank is so important

More than just an add on, a buffer tank is vital for an efficient biomass boiler system.

1. Boiler Performance

A solid fuel boiler does not have the same modulation or turndown capability as a gas fired appliance

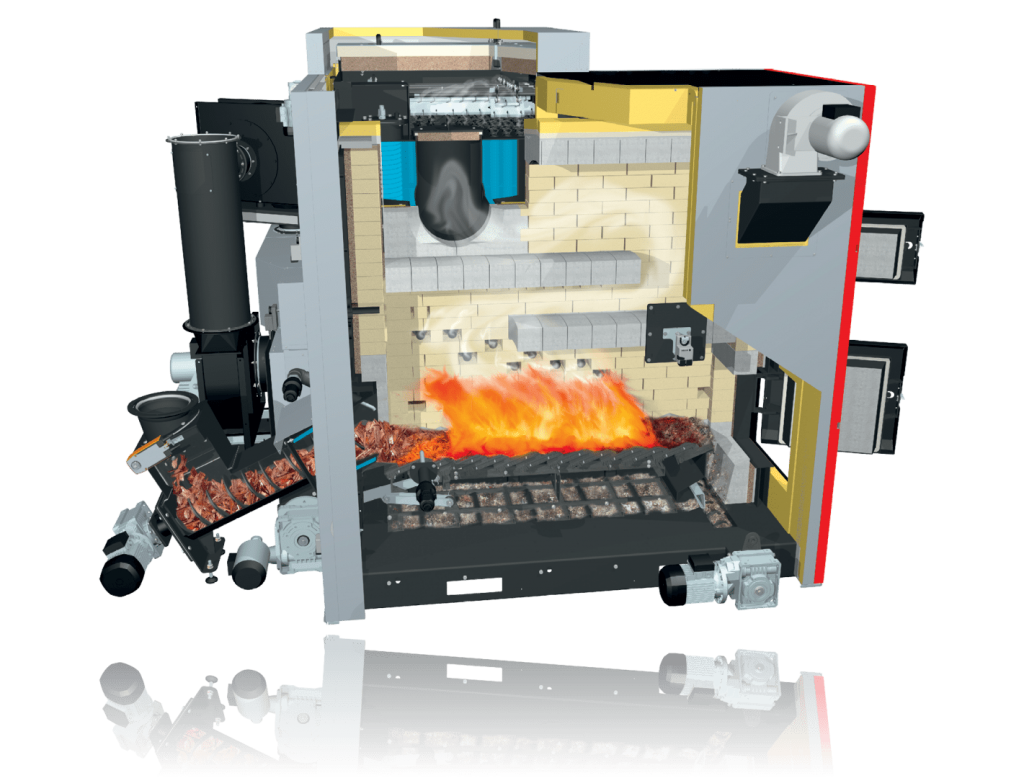

Unlike with gas burners, where you turn a valve and the flame stops, biomass boilers have to burn all of the fuel in the combustion chamber and in some cases, the fuel left in the fuel feel auger to reduce burn back. This can result in many kg of fuel being consumed, generating many kW of energy which are unneeded and unused. A correctly sized biomass boiler buffer tank will allow a boiler to dissipate the heat, storing it at a reasonable temperature ready for use.

Without a buffer tank the biomass boiler can overheat causing excessive wear and damage to combustion chamber – overheating of the wider system can occur which will result in inefficiencies and wasted fuel.

2. Multiple heat sources

A correctly sized biomass boiler buffer tank can create a neutral point to allow multiple heat sources/generators and many off-takes/heating loads to work in unison.

Without a large volume of water and hydraulic brake, multiple heat sources are not possible as you will cause pumps to fight against each other and generally an unbalanced system. Modern heating systems will often have high grade heat, mixed with low grade heat i.e a biomass boiler and a heat pump.

The low grade heat would be supplied by the heat pump, providing a base temp of 50˚c and the the biomass boiler would provide the high grade heat of 75˚c. Intelligent loading and discharging of a buffer tank means that you can layer the heat within the tank and have the two very different temperatures working together without conflict – lower temperatures can be taken from one layer for an application such as underfloor heating and the higher temperature drawn from upper level and used for DHW or high temperature emitters.

3. Log Boiler Efficiency

Many people find that a log boiler is best choice for them, due to the availability of logs, the lower capital cost of the equipment and space, however the nature of the boiler makes the sizing of a buffer tank important.

Typically a pellet boiler with good modulation would need an allowance of between 15-25 litres of buffer storage per kW. A log boiler would require an allowance of around 55 litres of buffer storage per kW – this is because once you light a log boiler, it stays lit until all of the fuel inside is consumed.

Burn times of the biomass boiler depend on fuel quality, however, an average burn time is around 4 hours and so the boiler design has to allow for heat dissipation for 4 hours from the boiler.

Request a callback

If you want to get a quote or simply ask a question, fill in your details on our Contact Page.